Sandblasting Booth consists of room structure, abrasive recovery system, sandblasting system, ventilation system, lighting system, electrical control system and other parts. When the machine is working, firstly start the dust removal system, abrasive separator, elevator, belt conveyor, lighting system, etc. in sequence, then load the workpiece outside the sandblasting room, and the workpiece enters the sandblasting room along the track, and when it reaches the set position , close the blasting room door. The operator hand-held a spray gun in the chamber to blast the workpiece to remove the oxide scale, welding slag and other attachments on the surface of the workpiece. After sandblasting, the falling sand enters the screw conveyor through the grid scraper, and is recovered into the sand storage box through the elevator and separator. The recovered clean abrasive is prepared for the recycling of the sandblasting machine. During sandblasting, the oxide scale, impurities and abrasives on the surface of the blasted workpiece are suspended and flooded in the entire blasting room in the form of dust, which directly affects the sight of the blasting operation and the cleaning of the workpiece. The equipped high-efficiency dust collector will come in time Collect dust generated during operation. Until the workpiece is cleaned, the door of the cleaning room is opened, and the workpiece exits the cleaning room to the unloading area. Some workpieces need to be flipped and sandblasted to clean up dead spots. Repeat this process until the work is completed, and stop in sequence.

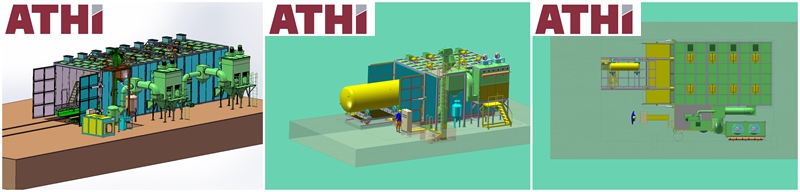

3D Solid Works Drawings of Custom Sand Blasting Booth

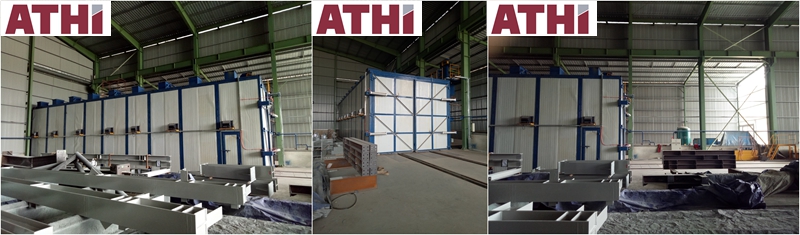

Sand Blasting Booth in Malaysa

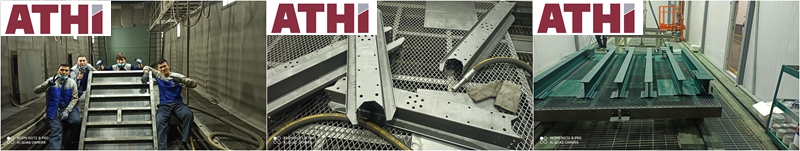

Sand Blasting Booth in Uzbekistan

Sand Blasting Booth in Indonesia

Sand Blasting Booth in Russia

It is suitable for surface cleaning of large steel structures, ships, bridges, aerospace, military products, rail equipment, wind power towers, port machinery, petroleum machinery, construction machinery, mining machinery, textile machinery, special vehicles, large castings, inner and outer walls of steel pipes, etc.

| Model | S665 | S666 | S865 | S866 | S1066 | S1566 |

| Room size(mm) | 6000×6000×5000 | 6000×6000×6000 | 8000×6000×5000 | 8000×6000×6000 | 10000×6000×6000 | 15000×6000×6000 |

| Size of workpieces(mm) | 3000×3000×2500 | 3000×3000×3500 | 5000×3000×2500 | 5000×3000×3500 | 7000×3000×3500 | 12000×3000×3500 |

Quantity of spraying guns(pcs) | 2 | 2 | 2 | 2 | 2 | 2 |

| Diameter of spraying nozzle(mm) | 6 | 8 | 10 | 10 | 10 | 10 |

Compressed air consumption(m3/h) | 2.2 | 3.92 | 6.1 | 6.1 | 6.1 | 6.1 |

Sand consumption (kg/h) | 650 | 1160 | 1800 | 1800 | 1800 | 1800 |

Spraying area(m2/h) | 6 | 10.7 | 16.7 | 16.7 | 16.7 | 16.7 |

1.All-floor scraper recycling design, no large foundation of traditional sandblasting room, saving large capital construction costs;

2.The overall equipment is a modular design with a fully assembled structure;

3.The driving system uses a cylinder, which is stable and reliable in operation and has a low failure rate;

4.The scraper adopts stepwise advancement, the material moves evenly and reliably, with low noise and long service life;

5.The required foundation depth is very small, only 300-500mm, which greatly reduces the production cost of the foundation.