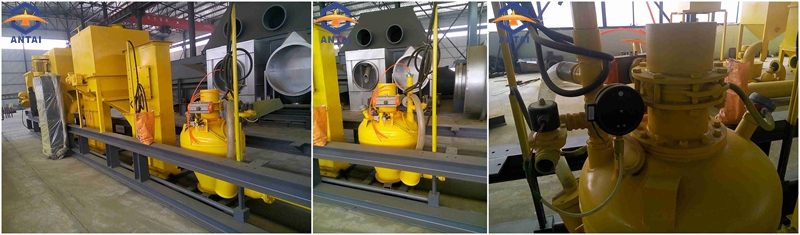

The pneumatic conveyor transport system is mainly used for the long-distance transportation and lifting of granular, powdery, loose and dry self-flowing materials, such as new sand, reclaimed sand, and broken old sand. During the transportation process, the material is fluidized and transported along the pipeline at a speed of 1-2m / s, which can ensure that the pipeline is not blocked, the wear is small, and the work is reliable. At the same time, it is not restricted by the direction of the conveying material and the number of pipelines, and it is convenient to realize the long-distance transportation and lifting of materials.

This product is equipped with a complete piping system including a spherical bow, a spherical tee, and a spherical unloader, as well as a flexible and reliable gas path system and an electronic control system; it can easily realize the sequence of multiple discharge points or select conveying. Easy to install.

Characteristics:

1. The entire sending process is fully automatic.

2. Long-distance transportation is possible. By setting tees and unloaders on the pipeline, the number of unloading points can be freely selected, that is, a pneumatic conveying device can complete the conveyance of one or more materials.

3. The material is filled with high-density and low-speed transportation of the pipeline, the pipeline wears little, the material is broken, the energy consumption is low, the maintenance cost is low, and the sand temperature changes during the transportation process.

4. Special ball elbow, ball tee and ball unloader are adopted for long service life.

5. It is convenient and simple to determine the conveying volume by adjusting the air volume.

6. No dust overflows during the whole transportation process, and the environment is not polluted.

7. Flexible layout.

Y9303 Pneumatic Conveyor Transport System

Y9305 Pneumatic Conveyor Transport System

Y9310 Pneumatic Conveyor Transport System

The

pneumatic conveyor transport system is mainly used for the long-distance

transportation and lifting of granular, powdery, loose and dry

self-flowing materials, such as new sand, reclaimed sand, and broken old

sand. During the transportation process, the material is fluidized and

transported along the pipeline at a speed of 1-2m / s, which can ensure

that the pipeline is not blocked, the wear is small, and the work is

reliable. At the same time, it is not restricted by the direction of the

conveying material and the number of pipelines, and it is convenient to

realize the long-distance transportation and lifting of materials.

This

product is equipped with a complete piping system including a spherical

bow, a spherical tee, and a spherical unloader, as well as a flexible

and reliable gas path system and an electronic control system; it can

easily realize the sequence of multiple discharge points or select

conveying. Easy to install.

| Model | Y9303 | Y9305 | Y9310 |

| Productivity(t/h) | 4~6 | 8~14 | 14~20 |

| Working pressure(Mpa) | 0.45~0.6 | 0.45~0.6 | 0.45~0.6 |

| Compressed air consumption(m3/min) | ≤1.2 | ≤2.4 | ≤2.4 |

| Horizontal transport distance(m) | ≤120 | ≤120 | ≤120 |

| Vertical transport height(m) | ≤12 | ≤12 | ≤12 |

1. The entire sending process is fully automatic.

2.

Long-distance transportation is possible. By setting tees and unloaders

on the pipeline, the number of unloading points can be freely selected,

that is, a pneumatic conveying device can complete the conveyance of

one or more materials.

3. The material is filled with high-density

and low-speed transportation of the pipeline, the pipeline wears little,

the material is broken, the energy consumption is low, the maintenance

cost is low, and the sand temperature changes during the transportation

process.

4. Special ball elbow, ball tee and ball unloader are adopted for long service life.

5. It is convenient and simple to determine the conveying volume by adjusting the air volume.

6. No dust overflows during the whole transportation process, and the environment is not polluted.

7. Flexible layout.