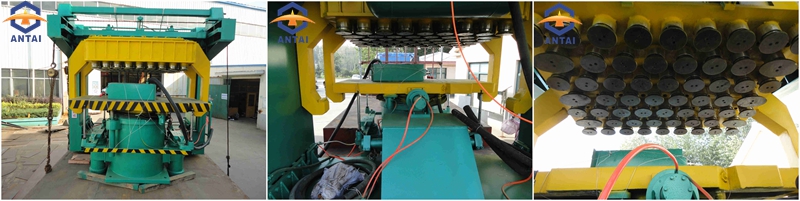

High pressure pneumatic hydraulic multi-pistons molding machine is

suitable for mass production of single molding plate or single molding

box of medium and small sized castings, which can produce cope or drag.

The machine adopts micro vibration compaction mechanism, large shock

force and compaction strength. So it can meet simple or complex molding

requirements withour pre-shock. It is one of the indispensable tools for mechanized molding and has gradually replaced traditional manual moldling.

This machine consisits of machine body, pattern stripping mechanism, jolting compaction mechanism, rocker arm pressure head part and pneumatic piping system.

ZD0806 High Pressure Hydraulic Multi-Pistons Moulding Machine

ZD1008 High Pressure Hudraulic Multi-Pistons Moulding Machine

ZD2010 High Pressure Pneumatic Multi-Pistons Moulding Machine

It's used for green sand moulding in various foundry workshops. the machine can be used in a single machine, or it can be used as a mechanized assembly line or a semi-automatic production line.

| Item | ZD0806 | ZD1008 | ZD1206 | ZD1409 | ZD1907 |

| Internal size of sand box(mm) | 800×630×300 | 1000×800×300 | 1200×630×300 | 1400×900×300 | 1520×1200×190 |

| Worktable size(mm) | 950×730 | 1150×850 | 1500×900 | 1500×900 | 1980×1080 |

| Working pressure(Mpa) | 0.58 | ≥0.55 | ≥0.55 | ≥0.55 | ≥0.55 |

| Multi contacts compaction stroke(mm) | 200 | 200 | 200 | 260 | 250 |

| Compaction ratio pressure(0.58Mpa) | 4.0kg/m2 | 3.8kg/m2 | 4.1kg/m2 | 4.5kg/m2 | 4.2kg/m2 |

| Jolt load(kg) | 350 | 750 | 2000 | 2500 | 1000 |

| Molding cyliner stroke(mm) | 300 | 350 | 350 | 350 | 350 |

| Max distance from worktable to contacts lower plane(mm) | 435 | 535 | 560 | 560 | 435 |

| Productivity(half box/hour) | 35~40 | 35~40 | 35~40 | 35~40 | 35~40 |

| Free air consumption | 2.5m3/half box | 2.5m3/half box | 2.5m3/half box | 3.0m3/half box | 3.0m3/half box |

| Overall dimension(mm) | 2175×1600×2380 | 2480×1980×2440 | 2410×2538×2632 | 2450×2978×2795 | 2740×2100×2900 |

1. This machine adopts pneumatic multi-contact compaction. Numbers of hydraulic contacts range from 48pcs to 128pcs in compaction according to different sizes of molding boxes.

2. When the machine is being pressued and shocked, the contact is compacted on one side and shocked with the workbench, higher hardness and uniform of sand molding.

3. This machine adopts spring full cushioning pneumatic micro-shock structure, so there is no special requirement for foundation.

4. The machine adopts the link synchronous shaft structure pneumatic oil investigation speed, good mold synchronization and free speed control.