【Model】: Q37

【Application】: Castings, forgings, welded parts, aluminum alloy parts and other heat-treated parts of various varieties, large, medium and small batches

【Characteristics】: Compact structure, high productivity

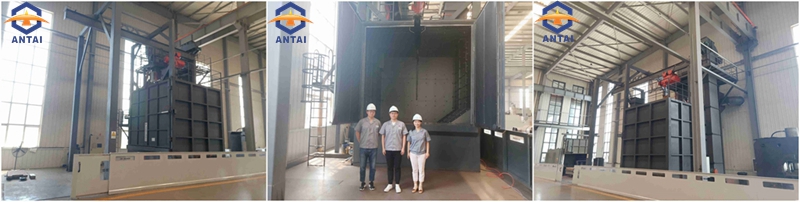

Hanger hook passing-through type shot blasting machine is a kind of hook type shot blasting machine, which consists of blasting chamber, elevator, separator, screw conveyor, blast wheel assembly, abrasive control system, hook walking track, hook system, rotation device, foundation, dust collecting system and electric control system.

Hanger hook shot blasting machine is applied to surface cleaning or strengthening treatment of Small and medium castings and forgings in chemical, motor, foundry, construction, machine tools and other industries. Especially suitable for surface cleaning or strengthening treatment of castings and steel structural works with multiple varieties and small batches to remove surface residual sand cores, burnt-on sand and oxide skin, suitable for slender and thin-walled parts.

Q378 1 ton Castings Hanger Hook Shot Blasting Machine

Q3730 3 ton Steel Weldments Hanger Hook Passing Through Type Shot Blasting Machine

Q3760 6 ton Motor Housing Hanger Hook Shot Blasting Machine

Q37100 10 ton Steel Weldments Hanger Hook Shot Blasting Machine

Q37200 20 ton Castings Hanger Hook Shot Blasting Machine

Hanger hook shot blasting machine is applied to surface cleaning or strengthening treatment of small and medium castings and forgings in chemical, motor, foundry, construction, machine tools and other industries. Especially suitable for surface cleaning or strengthening treatment of castings and steel structural works with multiple varieties and small batches to remove surface residual sand cores, burnt-on sand and oxide skin, suitable for slender and thin-walled parts.

| Item | Size of workpieces (mm) | Loading weight of single hook (kg) | Blasting capacity (kg/min) | Lifting capacity of elevator(t/h) | Separating capacity of separator(t/h) | Ventilation capacity(m3/h) | Power(without dust collecting system)(kw) |

| Q376 | φ600*1100 | 600 | 2*120 | 15 | 15 | 5000 | 19 |

| Q378 | φ800*1500 | 1000 | 2*200 | 22 | 22 | 8000 | 32.5 |

| Q3710 | φ900*1600 | 1000 | 2*250 | 30 | 30 | 9000 | 36.55 |

| Q3720 | φ1400*2300 | 2000 | 3*250 | 45 | 45 | 15000 | 61.27 |

| Q3730 | φ1600*2200 | 3000 | 3*250 | 45 | 45 | 15000 | 64.4 |

| Q3750 | φ1800*2500 | 5000 | 4*250 | 60 | 60 | 18000 | 78.4 |

| Q3780 | φ2000*3000 | 8000 | 4*250 | 60 | 60 | 20000 | 81.5 |

| Q37100 | φ2500*3500 | 10000 | 5*250 | 75 | 75 | 22000 | 105 |

| Q37160 | φ2600*4000 | 16000 | 6*250 | 90 | 90 | 25000 | 130 |

| Q37200 | φ3000*6000 | 20000 | 7*250 | 110 | 110 | 30000 | 100 |

| Q37300 | φ3500*5000 | 30000 | 7*250 | 110 | 110 | 30000 | 100 |

1. The

layout of blasting chamber and blast wheel is simulated by Solid Works

design software, specially designed by our senior designers.

2.

Adopt new type of hook sealing device, compact structure, which

effectively reduces or eliminated leakage of abrasives. The hook can

realize positive or negative rotation to ensure the cleaning effect.

3. Pneumatic control system is adopted to effectively prevent abrasive from being thrown and wounded.

4.

Large blasting capacity and high blasting speed turbine can

significantly improve cleaning efficiency and obtain satisfactory

cleaning quality.

5. 10mm rolled Mn13 steel plate in the blasting area with 12000 hours service life, resistant to impact and easy to replace.

6. Sufficient safety interlocking mechanism to ensure safety of operators.