【Model】: QWD

【Application】: Discs, sheets, castings, bodies and structural parts.

【Characteristics】: Compact structure, high productivity, small deformation, no pit.

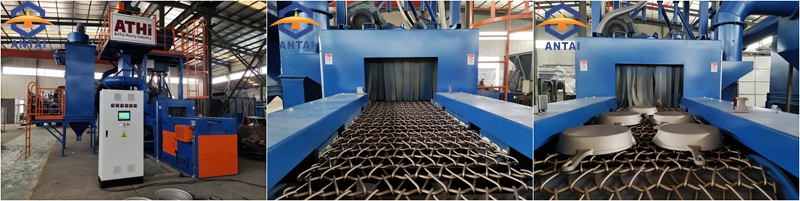

Wire Mesh Shot Blasting Machine consists of conveying system, blasting chamber, bucket elevator, blasting gate, maintenance platform, abrasive sand separating device, vertical screw conveyor, horizontal screw conveyor, high pressure blowing system, inlet housing, oulet housing, dust collecting system and electric control system.

It's mainly used in automobile, aerospace, railway and machinery manufacturing, specially cleaning discs, sheets, castings, bodies and structural parts, etc. It can apply strong blasting to surfaces of original steel and castings, remove its rust layer, welding slag and scale, and obtain a uniform metallic luster to improve coating quality and anti-corrision effect of the steel. The mesh belt allows the parts to pass through in an automatic, continuous uninterrupted manner, and accepts blast cleaning in different directions. The pivoting type of blast wheels maximizes blasting efficiency, and avoids collision of parts with each other and damages surface of the parts.

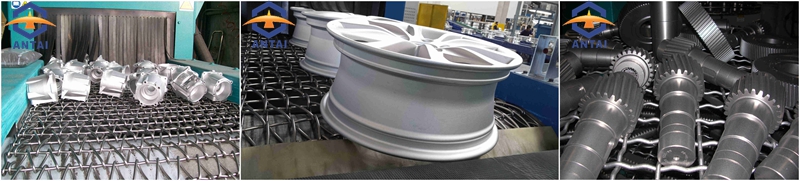

Cleaning Effect of Metal Wire Mesh Shot Blasting Machine

QWD80 Metal Wire Mesh Shot Blasting Machine Test Run and Shipment

It's mainly used in automobile, aerospace, railway and machinery manufacturing, specially cleaning discs, sheets, castings, bodies and structural parts, etc. It can apply strong blasting to surfaces of original steel and castings, remove its rust layer, welding slag and scale, and obtain a uniform metallic luster to improve coating quality and anti-corrision effect of the steel. The mesh belt allows the parts to pass through in an automatic, continuous uninterrupted manner, and accepts blast cleaning in different directions. The pivoting type of blast wheels maximizes blasting efficiency, and avoids collision of parts with each other and damages surface of the parts.

| Item | QWD60 | QWD80 | QWD100 | QWD120 |

| Wire mesh width (mm) | 600 | 800 | 1000 | 1200 |

| Blast wheel quantity (pcs) | 4 | 4 | 8 | 8 |

Cleaning speed (m/s) | 0.5~4 | 0.5~4 | 0.5~4 | 0.5~4 |

| Blasting power (kw) | 11~15 | 11~15 | 11~18.5 | 11~18.5 |

| Blasting capacity kg/min) | 4*120 | 4*120 | 8*180 | 8*250 |

1. The arrangement of blasting chamber and blast wheels is determined by computer 3D dynamic projection simulation.

2. Wire mesh structure, the advance speed of wire mesh can be frequency-adjusted, more uniform blasting and higher cleaning effect.

3. Steel mesh belt, the slag skin is easy to leak, good heat dissipation. It can realize effect cleaning of high temperature workpieces.

4. The number of blasting wheels can be determined according to sizes of workpieces, which can reduce unnecessary energy waste and unnecessary damage to the equipment.