【Model】: Z42

【Application】:Small and medium-sized castings, such as valves, mechanical parts, auto parts, hydraulic parts, pipe fittings, agricultural machinery parts, stove parts.

【Characteristics】: Easy operation, compact structure, high productivity, convenient maintenance.

Green Sand full automatic horizontal flaskless moulding line is used to manufacture sand castings. The loose molding sand are automatically injected into the sand molding box, automatic compaction, automatic mold release, automatic box closing, automatic pattern stripping, automatic pushing out and automatic pouring. The sand box is pushed into the sand mixer so that it is continuously produced.

Z425 Auto Parts Automatic Horizontal Flaskless Moulding Machine

Z426 Auto Parts Automatic Horizontal Flaskless Moulding Machine

Z427 Auto Parts Automatic Horizontal Flaskless Moulding Machine

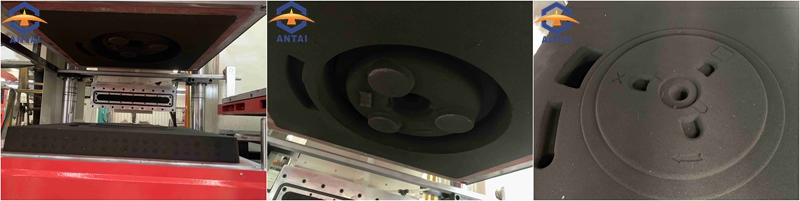

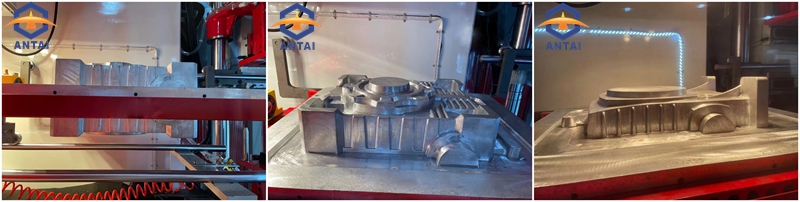

Patterns for Automatic Horizontal Flaskless Moulding Machine

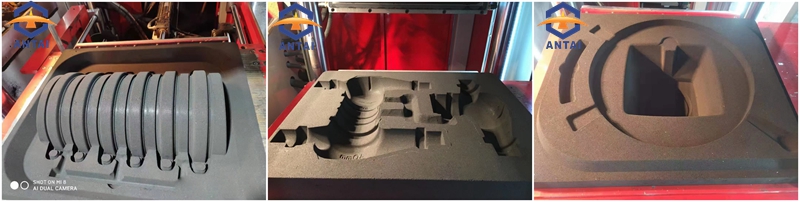

Sand Mouldings for Automatic Horizontal Flaskless Moulding Machine

The full automatic horizontal flaskless moulding machine adopts way of horizontal molding, which is suitable for the production of small and medium-sized castings such as valves, mechanical parts, auto parts, hydraulic parts, pipe fittings, agricultural machinery parts, stove parts, brake discs, bearing caps, automobile castings, diesel castings, sewing machine castings, motor covers, water pump castings, etc., and is suitable for the production of ductile iron and grey iron, ash, mellable steel, non-ferrous metals and other materials.

| Item | Z425 | Z426 | Z427 | LZ425 | LZ426 | LZ427 |

| Sand casting mould(mm) | 500×400×120~150 550×450×120~150 | 610×508×130~180 660×508×130~180 | 700×600×130~180 600×600×130~180 | 500×400×120~150 550×450×120~150 | 610×508×130~180 660×508×130~180 | 700×600×130~180 600×600×130~180 |

| Productivity(second/mould) | 36~40 | 40~45 | 40~45 | 40~45 | 45~50 | 45~50 |

| Compaction pressure(Mpa) | 0.7~0.9 | 0.7~0.9 | 0.7~0.9 | 0.7~0.9 | 0.7~0.9 | 0.7~0.9 |

| Air consumption(m3/min) | 1.6 | 2 | 2.2 | 1.6 | 2 | 2.2 |

| Operating oil pressure(Mpa) | 8.5 | 10.6 | 9.2 | 8.5 | 10.6 | 9.2 |

| Power(kw) | 15 | 18.5 | 22 | 15 | 18.5 | 22 |

Molding sand consumption (t/h) | 8.6~12 | 10.5~17 | 12~22 | 8.6~12 | 10.5~17 | 12~22 |

1. Accept customized equipment based on customers' exact requirements.

2. Greatly improve production efficiency and save labor costs.

3. Small occupied areas and save land .

4. Improve casting quality and stability, high sand molding compactness.

5. The height of the sand box can be adjusted and set according to the thickness of the molding box.

6. Can be equipped with conveyor lines, can also be produced in a single machine.

7. The hydraulic and electronic control parts of the machine are all imported components, which are stable, reliable, high precision, long life and long life.